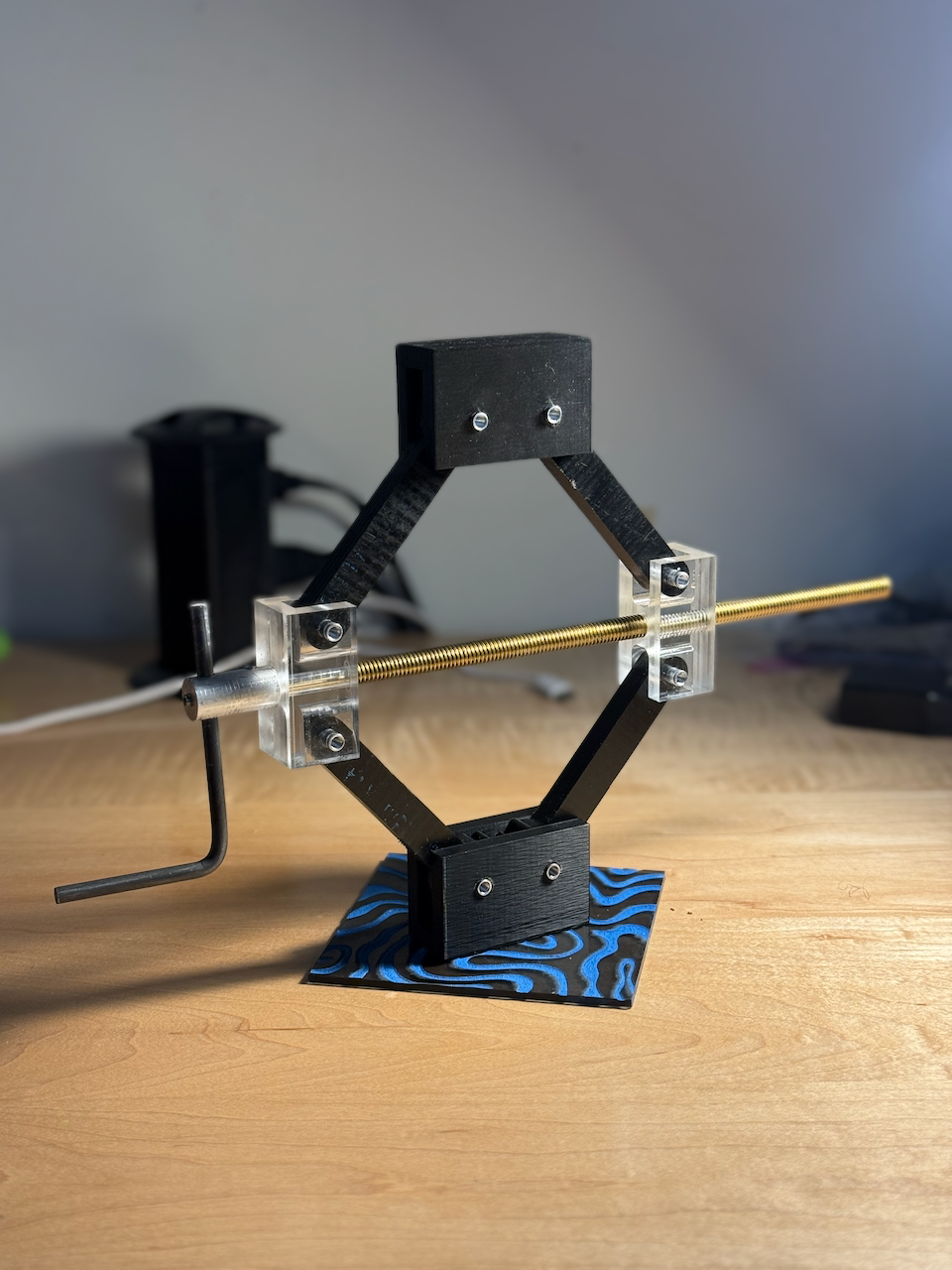

Additive and Subtractive Manufacturing for Car Jack

Completed a comprehensive manufacturing project resulting in a fully functional scissor jack. The project required translating engineering drawings into fabricated mechanical components using CAM software, CNC mills, 3D printers, lathes, drill presses, and other shop equipment. This work strengthened my proficiency in precision machining, CAD/CAM integration, and mechanical assembly, while reinforcing the application of manufacturing best practices to achieve high accuracy, efficiency, and reliable functional performance.

Skills Utilized

CNC Milling

The side blocks, made of clear acrylic were milled on a Tormach 770M PCNC mill

The four jack links, made of black delrin, were milled on a Tormach 770M PCNC mill

CAM

All CAM operations for the above parts were completed in Autodesk Fusion 360

3D Printing

The top and bottom blocks, 3D printed out of PLA, were completed on a Bambu Lab A1 Mini printer

Turning (Lathe)

Both the aluminum end cap and the threaded brass rod were turned on a TRAK 1630RX lathe

Laser Cutting

The patterned jack base was laser cut and etched on an LS-2440 BOSS laser cutter

Drill Pressing

The aluminum end cap was drill pressed to fit the steel turning bar and the threaded brass rod